Industrial Manufacturing Labels Engineered for Performance

Support Scale. Safeguard Accuracy. Stand Up to Daily Demands.

From compliance to traceability, industrial manufacturers need labels that endure the pressures of production, the rigors of field use and the demands of regulatory standards. Armis delivers complete durable label solutions – labels, tags, printers, applicators and ribbons – built for durability, accuracy and long-term performance. All backed by materials science and proven performance.

Through the combined strengths of IDENTCO, Reliance and Trebnick, we help reduce complexity, control costs and improve label reliability across manufacturing, warehousing, distribution and industrial operations.

Labels Built for Industrial Applications

Our durable label solutions are designed to perform in the most demanding industrial environments. Whether inside high-heat machinery, on textured equipment surfaces or across complex production lines, we deliver labeling systems that ensure safety, clarity and durability at every step.

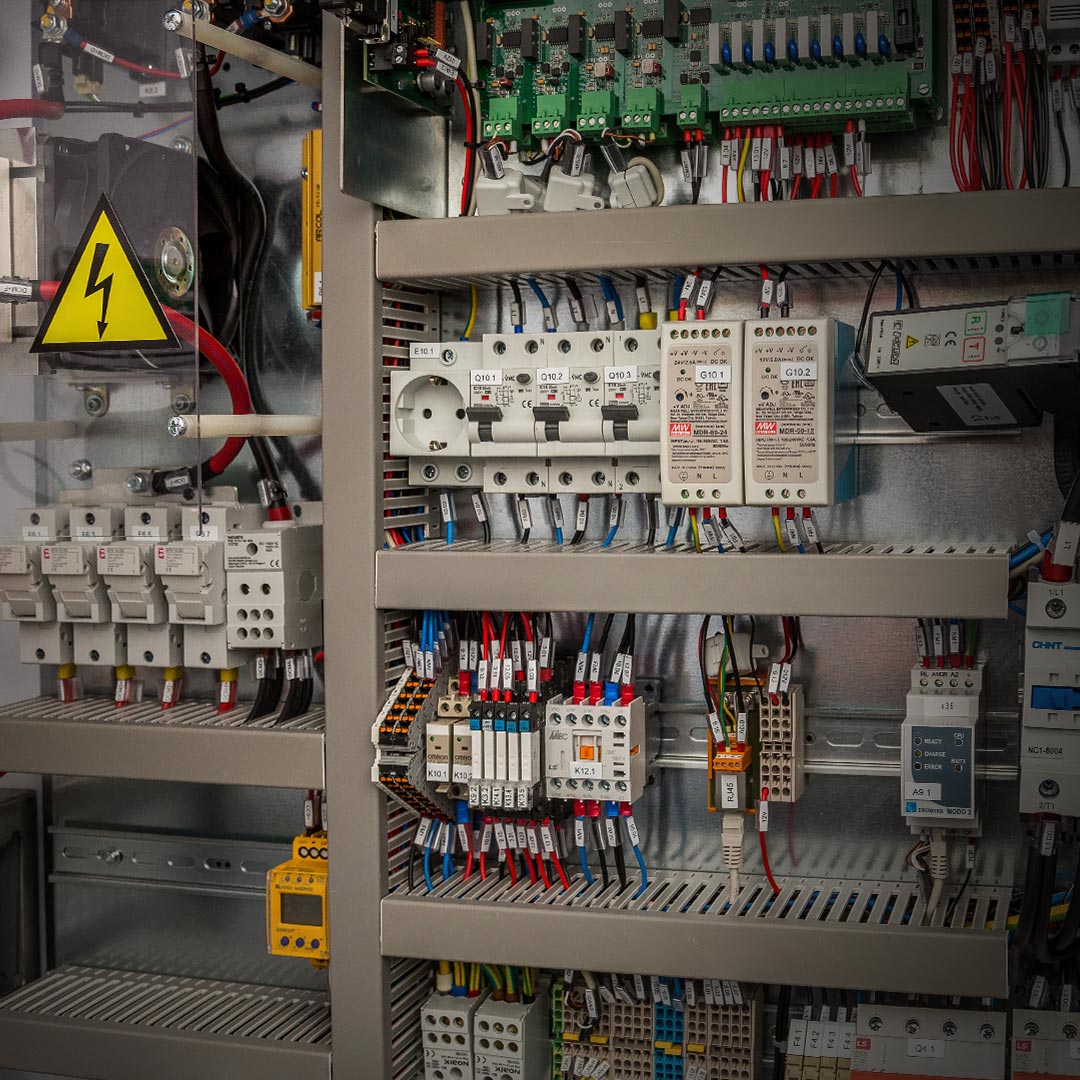

Electrical Distribution Equipment Labels

Labels inside electrical panels, switchgear and power distribution units must deliver lasting legibility, adhesive strength and compliance within controlled indoor environments. These labels play a critical role in equipment identification, safety communication and lifecycle tracking for systems like circuit breakers, fuse blocks, panelboards and switchgear assemblies. Armis designs label constructions suitable for clean, enclosed settings using a range of materials – including paper, polyester and vinyl – to balance durability with cost-efficiency.

-

Standards-aligned materials: Available in UL, cUL and CSA-recognized constructions tailored for indoor electrical applications.

-

Print and color systems: Support high-contrast visuals, arc flash warnings and color-coded indicators for quick service reference.

-

Material flexibility: Includes durable papers for protected placements alongside polyesters and vinyls for more demanding spots.

-

Adhesive compatibility: Formulated for smooth and textured metals, coated housings and enclosure interiors.

-

Lifecycle performance: Label systems resist abrasion, incidental contact, and indoor service conditions to support inspections and maintenance.

Labels for Appliances

Appliance manufacturers rely on labeling systems that support product branding, user safety and regulatory compliance while integrating seamlessly into production environments. Labels are applied across control panels, housing exteriors, interior compartments and in-drum locations, often exposed to heat, moisture and frequent handling. Armis delivers more than materials. We provide complete label solutions designed for second-surface protection, variable data printing and consistent brand execution across models and workflows.

-

Second-surface constructions: Protect printed graphics in high-moisture, high-heat environments such as dishwashers, dryers and washing machines.

-

Consistent color reproduction: Advanced print systems maintain accurate brand colors and finishes across models and production lines.

-

High-durability materials: Polyester and specialty films engineered for in-drum exposure, appliance housings and user-facing interfaces.

-

VMI and production support: Vendor-managed inventory programs help reduce waste and align with just-in-time workflows.

-

Cost-efficient converting: Scalable print and finishing processes meet both regulatory and branding needs across product lines.

Labels for Industrial Operations

Industrial manufacturing environments demand label solutions that support visibility, traceability and long-term performance under real-world stress. From production floors and assembly lines to warehouses and control rooms, Armis delivers rugged label solutions designed to integrate with printing systems, automation and inventory workflows. Our materials and formats are optimized for real-world use, withstanding abrasion, chemicals and frequent handling across a wide range of industrial applications.

-

Track and trace labeling: Supports serialized data, barcodes and part numbers across components, assemblies and work-in-process.

-

Instructional and control panel labels: Maintain long-term legibility on equipment, enclosures and operator interfaces.

-

Branding labels: Engineered for durability and adhesion on industrial housings, machinery and high-touch surfaces.

-

Wire and cable identification: Designed for routing accuracy and lasting readability during installation and field use.

-

Rating and nameplates: Provide permanent identification for equipment specs, safety info and regulatory markings.

Labeling Expertise for Industrial Manufacturing

We support industrial manufacturers with high-performance label solutions that meet evolving compliance, safety and performance needs across industrial environments.

- UL, cUL and CSA compliant materials for safety, nameplate and equipment labeling.

- Second-surface and durable constructions for extreme environments and abrasion-prone areas.

- Low surface energy adhesives for bonding to difficult industrial substrates.

- Advanced converting and printing technologies that reduce manufacturing costs.

- Color matching systems for consistent brand identity and accuracy.

- Inventory management support including VMI and consignment programs for JIT environments.

- Rapid prototyping and testing with production-level samples in 48 hours.

- Total cost assessments that reduce long-term labeling spend by 10 percent to 30 percent.

- Our solutions are engineered to meet ISO standards, optimize labeling programs and support full-lifecycle performance.

Knowledge Center

Technical Data Sheets

Explore❯

Case Studies

Explore❯

Insights

Explore❯

Armis’ family of brands brings decades of experience supporting industrial manufacturers with labeling systems that meet the toughest requirements. From finished product labeling to wire and cable ID and in-process traceability, our collective portfolio is engineered to solve complex challenges, improve cost efficiency and ensure lasting performance.

Together, IDENTCO, Reliance Label Solutions and Trebnick Systems help customers streamline labeling programs, consolidate supplier relationships and stay ahead of evolving standards – with technical expertise, responsive support and global reach