Confident Label Performance Starts with Proven Testing

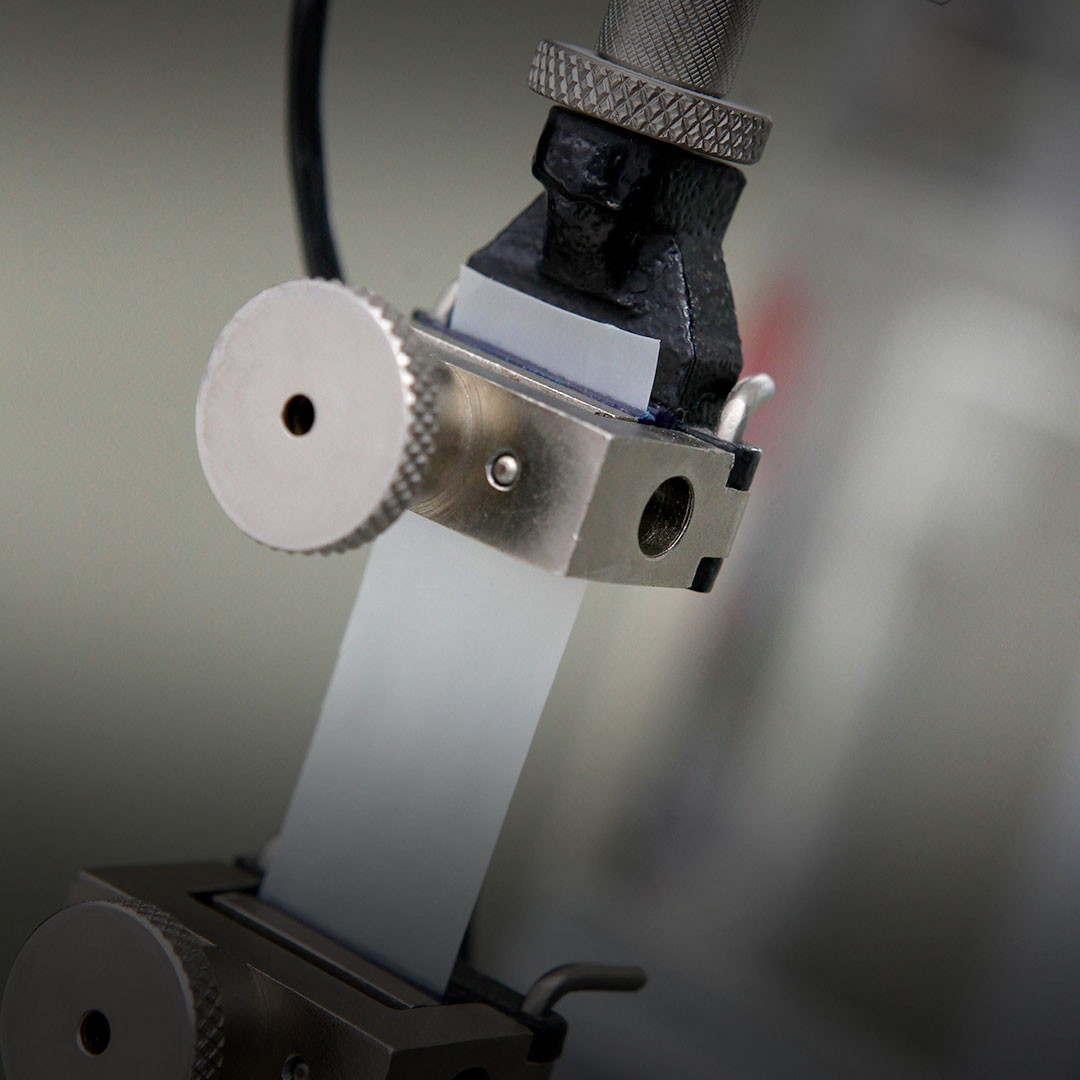

The performance of your labels is too critical to be left to chance. At Armis, our Label Geeks™ validate every construction, adhesive and print method through rigorous lab and performance testing built around real-world conditions. From heat and chemicals to abrasion, UV and surface variation, we ensure your labels meet the performance demands of your application – and the compliance standards of your market.

Our team works closely with yours to qualify materials, simulate end-use environments and troubleshoot early, so your labels perform on every product – every time. Whether you’re certifying against global regulations, validating a custom structure or simply verifying print durability on a new surface, we’ve brought together experts from premier durable label brands to help you move forward with confidence.

Real-World Conditions. Real Results.

We simulate the toughest environments and analyze every phase of label performance to proactively uncover challenges and find long-lasting solutions.

Application-Specific Testing

Every environment is different and we test like it. Our labs replicate real-world conditions like surfaces, materials and conditions, helping ensure label accuracy, functionality and visual integrity in the field.

-

Adhesion to curved, textured or low-surface-energy substrates.

-

Durability on metals, plastics, powder-coated or treated surfaces.

-

Compatibility with ink systems and thermal transfer ribbons.

-

Liner performance during die-cutting, application and dispensing.

-

Lifecycle testing to assess fading, curling, tearing or delamination.

Reliability Tests

We compress time to predict long-term performance. Through accelerated aging and stress simulations, we reveal how labels perform over months or years – identifying potential points of failure and helping optimize construction before deployment.

-

Thermal aging to simulate years of heat exposure.

-

Mechanical flexing and abrasion to test physical durability.

-

UV exposure to measure resistance to fading or material breakdown.

-

Edge-lift and adhesive fatigue over prolonged use.

-

Lifecycle simulation under combined environmental factors.

Functionality Analysis

Labels must do more than stick. They must remain legible, scannable and intact throughout their intended life and beyond. Our functionality testing evaluates how a label performs under stress, ensuring critical content stays readable and construction holds up in everyday use.

-

Barcode and serial number retention under abrasion or exposure.

-

Protective laminate endurance through repeated handling.

-

Adhesion under fluctuating moisture, oils or chemicals.

-

Print clarity after environmental or mechanical stress.

-

Evaluation of structural integrity during flexing, impact or use.

Extreme Environmental Conditions

For labels used in the harshest applications, we replicate those extremes in a controlled lab environment. These tests validate durability under environmental forces that would break down standard labels – providing assurance your labels won’t fail when conditions shift.

-

UV and solar exposure for outdoor and high-light conditions.

-

Salt spray for corrosion resistance in marine or industrial settings.

-

Chemical soak and wipe tests for acids, fuels, oils and solvents.

-

Freeze-thaw and thermal cycling for temperature fluctuation resilience.

-

High humidity, submersion and condensation exposure.

- In-House Testing CapabilitiesOur state-of-the-art testing labs are fully equipped to deliver faster validation cycles, better material matching and quicker qualification turnarounds.

- Certification ExpertiseUL, cUL, RoHS, REACH, BS 5609 and other global regulatory standards – supported through validated constructions, documentation and ongoing compliance tracking.

- Custom ConstructionsEngineered materials tailored for heat, chemical, abrasion and substrate-specific demands.

- OEM and Regulatory AlignmentTesting protocols and qualification data to meet customer specs and formal approval processes.

Proven Performance Starts Here

From engineered materials to integrated systems and support, Armis delivers durable label solutions that meet the demands of your environment. See how our expertise translates across industries and applications.

Electronics & Components

Specialty Chemical

Building & Construction

Energy & Power

Durable Outdoor

Transportation

Industrial Manufacturing

Power Tools

Warehouse & Logistics

Healthcare