Custom Design That Solves Real-World Labeling Challenges

When stock options fall short, Armis delivers custom label solutions that help you move faster, reduce labeling errors and stay aligned with compliance and brand standards. From concept to press-ready file, we combine design precision with material and regulatory expertise – so your labels not only look right but perform as expected.

With experience across GHS labeling, industrial manufacturing, chemical packaging and high-mix environments, we bring together the design, pre-press and engineering capabilities of IDENTCO, Reliance and Trebnick to meet the demands of complex applications – with less rework and greater control over your end product.

Custom Solutions.

Designed to Your Specifications.

Our custom solutions are shaped by how your labels will be used – how they apply, how they perform and how they work under real-world conditions.

Graphic Design Support

Accurate labels start with well-prepared files. Our graphics teams bring decades of experience in designing, adjusting and preparing labels for production – across a wide range of materials, formats and print technologies. Whether you’re updating artwork, aligning with brand standards or building out regulatory content, we make sure your label looks right and prints cleanly.

-

Layout adjustments to support readability, branding and compliance.

-

File recreation or clean-up for spot or process printing.

-

Integration of logos, color targets, hazard symbols and variable fields.

-

Color matching and consistency across materials and print platforms.

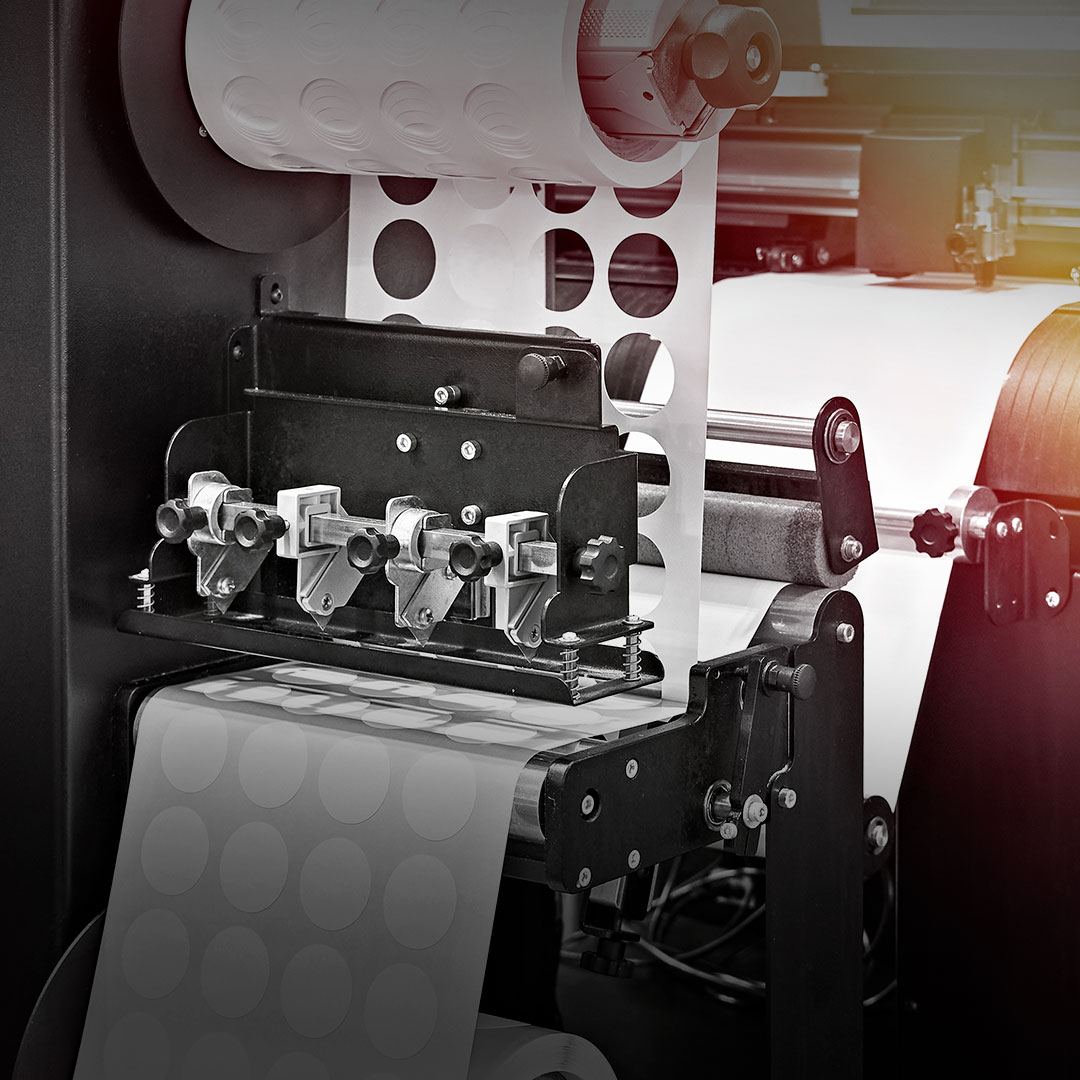

Label Construction Flexibility

We bring best-in-class materials science knowledge and converting capabilities to develop custom label formats that meet the technical demands of your application. From performance in extreme environments to compatibility with automation and printers, we help ensure each label functions precisely as needed.

-

Custom die cuts, curved formats and extended-length labels.

-

Roll-to-roll and auto-apply configurations.

-

Sensor marks and registration features for print alignment.

-

Material pairing for surface type, adhesive needs and durability.

- Construction options for OEM alignment and specialty formats like tamper-evident or multi-layer labels.

Graphic Accuracy and Brand Alignment

Clear visuals and consistent branding are critical for both compliance and presentation. Our teams support you from layout through production. Together, we help you fine-tune files, manage color and ensure print-ready output across systems and substrates.

-

Pre-press support for logo placement, layout and print readability.

-

Spot and process color matching for brand consistency.

-

Re-creation or cleanup of client files for press optimization.

-

Graphic integration within GHS and compliance label formats.

GHS Chemical Label Customization

We design GHS-compliant labels that meet regulatory guidelines and accommodate specialized formats, materials and application challenges. Whether you’re labeling drums, totes or curved containers, we build solutions that align with your use case.

-

Custom configurations for drums, totes, secondary containers and curved surfaces.

-

Accurate placement of hazard symbols, signal words and precautionary statements.

-

Material selection for chemical resistance and long-term exposure.

-

Die-cut flexibility for application-specific challenges.

-

Support for BS 5609 certification, compliant adhesive selection and print method compatibility.

Customized for Launch, Not Delay

We support more than design. We help you manage your lead times, production cycles and inventory needs to keep operations on schedule.

- Rapid PrototypingWe move quickly from design to physical samples, giving you fully functional prototypes for testing and approval to help your team make informed decisions, faster.

- New Product IntroductionWhether you’re in concept, pilot or pre-launch, we collaborate early to ensure your label is built to meet application needs, print correctly and deliver consistent performance from the start.

- Maintained Stock ProgramsWe’ll inventory your approved custom labels in our climate-controlled facility for fast turnaround and no production delays.

Let’s Design What You Need Next

From regulatory-driven requirements to brand-specific visuals and material challenges, Armis brings together the expertise to solve your exact environment’s challenges. Explore how we support specialized needs across industries.

Electronics & Components

Specialty Chemical

Building & Construction

Energy & Power

Durable Outdoor

Transportation

Industrial Manufacturing

Power Tools

Warehouse & Logistics

Healthcare