Electronic Component Labels Built for Precision and Protection

Protect Components and Maintain Traceability from Solder to Shipment.

In electronics and data centers, your labels have to withstand some of the harshest conditions in manufacturing. IDENTCO brings deep expertise in these environments, where labels must survive reflow soldering temperatures above 250 degrees Celsius, aggressive flux removers and solvents, static-sensitive processes and years of operation without degrading. When a label fails, it can break traceability, trigger compliance issues or halt operations.

That’s why durable label solutions require more than ink and adhesive. They demand expertise in materials science, regulatory standards and automated line integration. Our solutions are engineered specifically for the electronics sector – delivering precision labeling solutions trusted by leading OEMs for their accuracy, durability and seamless integration into high-speed production environments.

Electronic Labels Engineered for Every Environment

From high-speed production to real-world use, our solutions meet the demands of electronics by delivering precision, durability and compliance across the full product lifecycle.

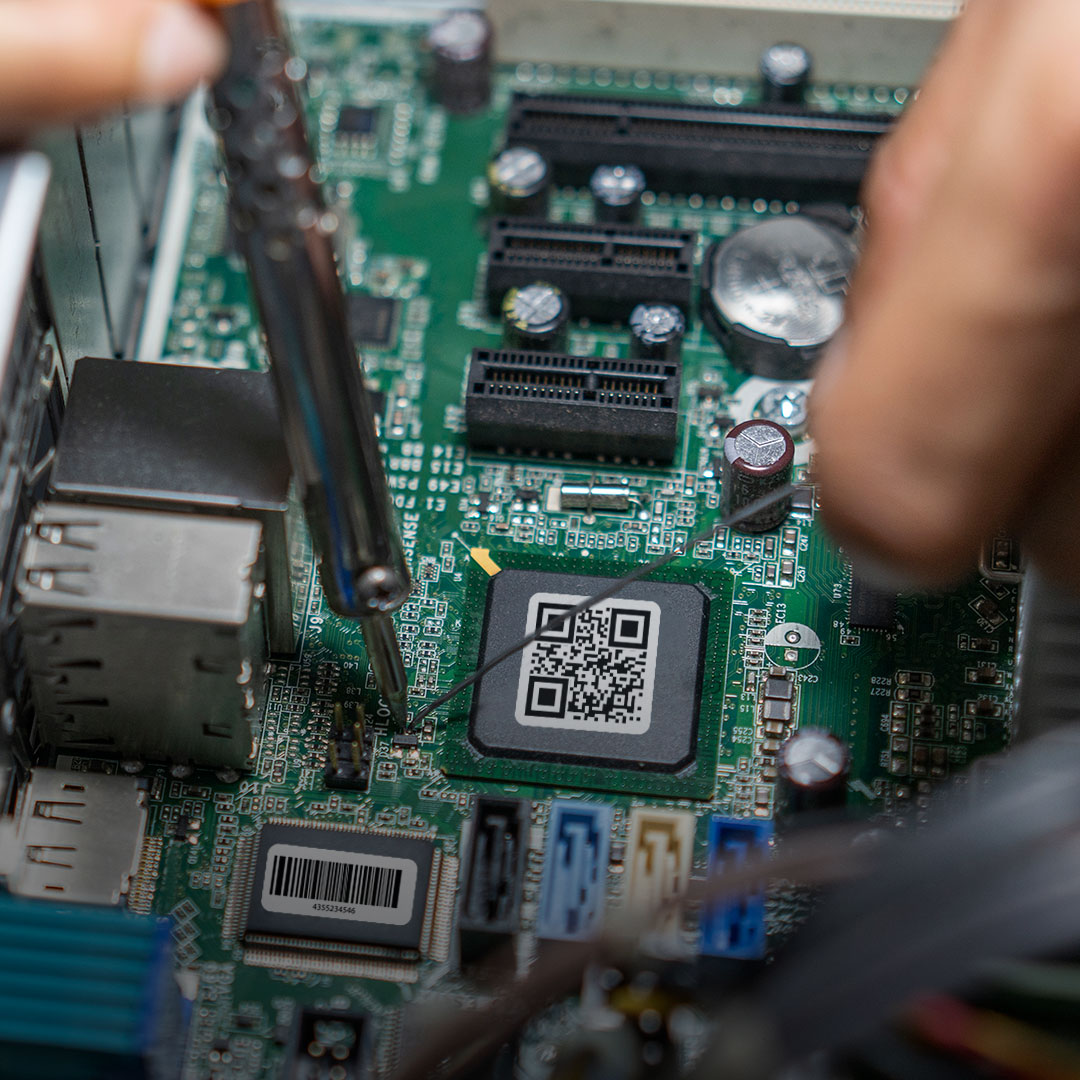

Printed Circuit Boards (PCB) & Electronic Component Labels

Printed circuit boards (PCB) and electronic components require labels that can survive the harshest processes in electronics manufacturing. Enabling tracking during production, assembly, maintenance and rework, PCB labels help identify part numbers, revision numbers, safety information even instructions regarding assembly and testing of the board. From tight enclosures to complex assemblies, our solutions are engineered for durability, compliance and precision in high-performance production environments.

- Low and high-heat options: Complete and scalable portfolio that covers both SMT reflow and non-SMT assembly processes.

- Small-scale precision: Micro labels as small as 3mm x 3mm for compact applications.

- Material durability: Withstand solder reflow, wave soldering and chemical washdowns.

- Certified reliability: UL and cUL materials and ribbons for proven reliability.

- Automation: Presenters and feeders to deliver complete durable label systems for PCB labeling.

- End-to-end traceability: Built for 100% visibility from production to field.

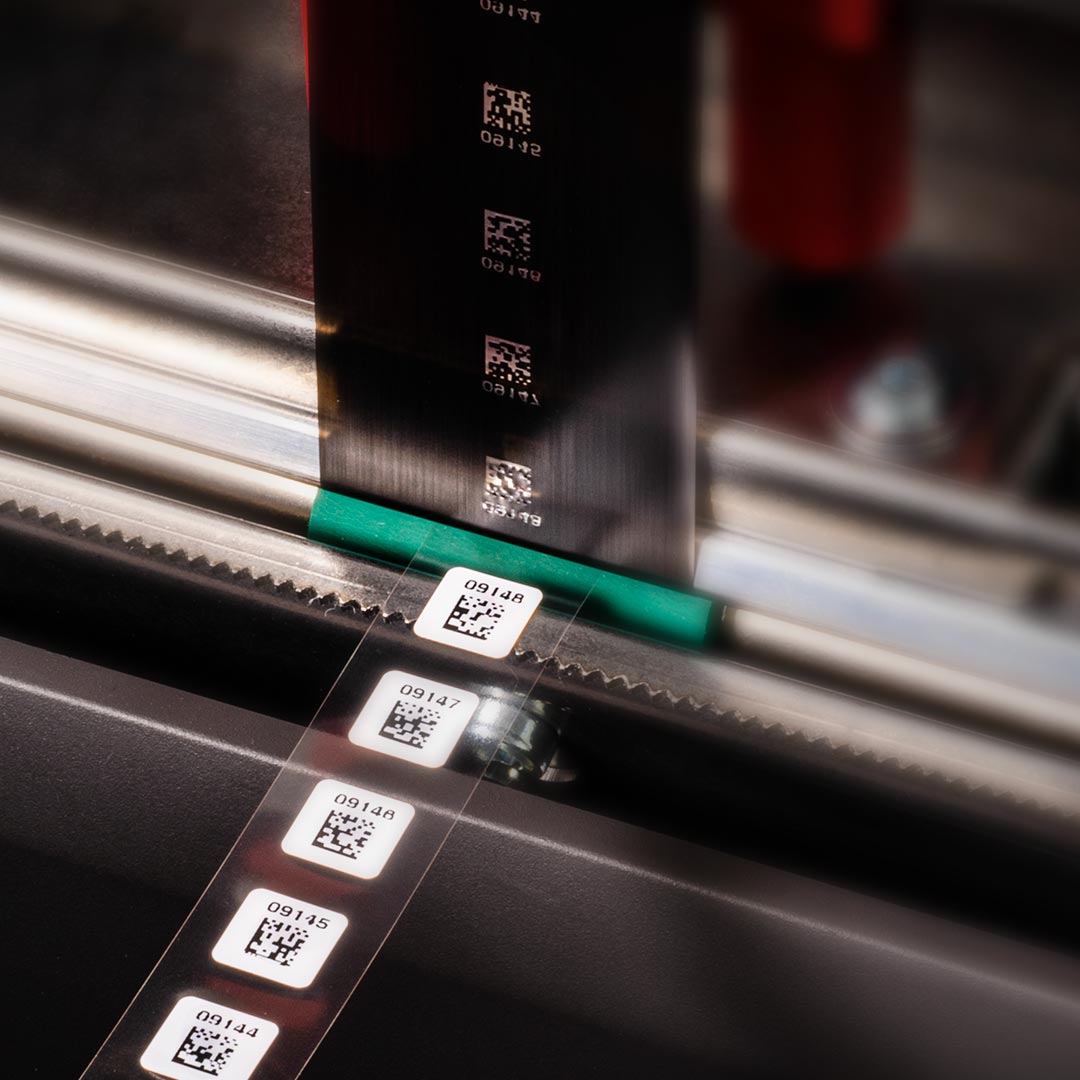

Wire & Cable ID

Incorrect or inconsistent cable identification limits your organization’s productivity – and could result in complex outages. Wire & Cable Identification solutions will help you easily identify cables or harnesses, especially in complex systems with numerous connections. With solutions for manual assembly, semiautomatic or automatic application during the wire, cable and harness manufacturing process, our solutions maximize efficiency, make troubleshooting easier and keep your team safe while maximizing productivity.

- Self-laminating / wraparound solutions: IDENTCO’s TT337 self-laminating solution delivers wire and cable ID in environments requiring long-term readability and protection.

- Small-space flagging solutions: Our TT757 fold-over label solution for small diameter or space-constrained wires where wraparounds don’t fit.

- Durable performance: UV-, chemical- and abrasion-resistant construction for mission-critical environments.

- Thermal transfer print technology: Designed for thermal transfer printing for high-resolution, durable output.

Compliance-Ready Box Build Assembly Labels

Labeling in box builds isn’t just a requirement. It’s critical for compliance, traceability and production readiness. Our Box Build Assembly durable label solutions – including constructions like TT403, TT406 and TT433 – support clear, durable identification across enclosures, components and subassemblies. From serial and rating plates to internal part marking, our labels are engineered for harsh environments and available in formats that fit both manual and automated workflows.

- Standards-compliant materials: UL, CSA and cUL recognized constructions including polyester and polyimide films.

- Heat- and solvent-resistant: Designed to withstand harsh chemicals, elevated temperatures and abrasion.

- Flexible print options: Supports thermal transfer, laser and pre-printed workflows for production efficiency.

- Long-term legibility: UV-stable topcoats and durable polyester or polyimide films protect print integrity over time.

- Reliable adhesion: Bonds to powder-coated metals, plastics and low-surface-energy materials.

Precision Solutions for Consumer Electronics Labels

As devices become more compact and performance demands grow, labels must support high-volume assembly, tight tolerances and product longevity. Armis’ electronics labeling solutions are engineered to perform in demanding environments, maintaining legibility, adhesion and compliance from the production floor to the hands of the consumer. Whether you’re marking internal components, branding housings or tracking devices through their lifecycle, our constructions deliver reliable, unobtrusive identification.

- Low-profile constructions: Thin, durable products like TT403 and TT757 fit compact assemblies without sacrificing readability or performance.

- High-temperature durability: TT433 polyimide labels resist elevated heat, abrasion and post-assembly cleaning agents.

- Clean-release masking: Temporary films protect delicate surfaces and displays during production.

- Serialized traceability: TT406 and TT403 support thermal transfer or pre-printed variable data for lifecycle visibility.

- Tamper-evident options: Secure constructions discourage counterfeiting and protect product authenticity.

High-Performance Labels for Data Centers

In high-density, mission-critical environments, precision matters. Our data center labeling solutions are engineered for legibility, reliability and speed across equipment, cables and infrastructure. Built for tight spaces and airflow-heavy environments, our labels maintain performance through elevated heat, vibration and constant service activity to help teams maintain uptime, compliance and clarity at every turn.

- Equipment identification: Durable constructions like TT403 and TT406 deliver long-term clarity on servers, switches and power systems.

- Cable and port labeling: TT337 self-laminating labels and TT757 fold-over flags enable precise wire ID in dense routing and constrained spaces.

- Heat- and abrasion-resistance: High-performance polyester and polyimide films stand up to airflow, vibration and repeated technician handling.

- Serialized asset tracking: Thermal transfer-compatible constructions support accurate lifecycle tracking from install to decommission.

- Tamper-evident options: Secure labels help prevent unauthorized swaps or access to critical hardware.

Where Electronics Demand More, We Deliver Durable

Every product is backed by rigorous testing and deep technical expertise, so you get solutions that integrate seamlessly, perform reliably and keep pace with the demands of modern electronics manufacturing and use.

We continuously raise the bar for durable label solutions in the electronics industry, delivering systems that perform under pressure and support your operations end-to-end.

- Superior micro-miniature labels and SMT solutions for space-constrained, automated precision environments.

- Wire and cable markers that keep assemblies organized and serviceable.

- Blank or custom-printed polyimide and polyester labels engineered for harsh processes.

- Thermal transfer printers and ribbons optimized for lasting readability and durability.

- Feeder systems compatible with leading pick-and-place machines, including IDENTCO’s ILP Series.

- Label design support to ensure the right solution is specified from the start.

- Dedicated customer service and technical support to keep production moving.

Knowledge Center

Technical Data Sheets

Explore❯

Case Studies

Explore❯

Insights

Explore❯

Armis makes electronics labeling simple and reliable with IDENTCO – a product line built on materials science, speed and service to support printed circuit boards (PCBs), wire and cable identification, electrical components and data center environments. These labels withstand high heat, harsh cleaning processes and static-sensitive environments, ensuring traceability and compliance where failure isn’t an option.

Now, as part of Armis’ durable label solutions, the same proven products come with greater scale, deeper technical expertise and a global support network – helping you move faster and reduce risk.