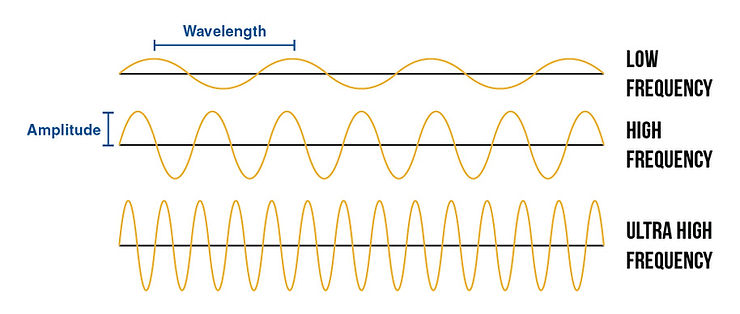

Frequency

Frequency is at the heart of how RFID works. RFID antennas transmit electromagnetic radio waves to read and locate RFID inlays. Radio waves can travel at three different frequencies; Low Frequency (LF), High Frequency (HF), or Ultra-High Frequency (UHF). In terms of waves, amplitude refers to the “height” of a wave, measuring the distance from its resting point to its peak. The more amplitude a wave has, the stronger it is. Wavelength is the “length” of a wave, measuring the distance between two consecutive peaks, representing a single wave cycle. Longer wavelengths will have a lower frequency and vice versa. The frequency is the number of wave cycles passing a fixed point per second, measuring how fast the wave oscillates.

UHF is the most common frequency used as these RFID inlays are the most cost-effective. They have the highest read range but can struggle in some environments. UHF radio waves can struggle to pass through metal or liquids, but LF and HF are more successful in these settings. As a general rule of thumb, the lower frequencies give you the most accurate readings with minimal interference. While the higher frequencies will provide you with the longest read range.

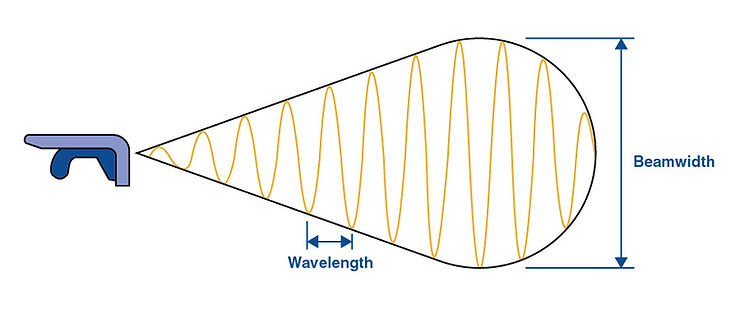

Beamwidth

Distance matters with RFID! Do you intend to use RFID for more targeted-based identification of individual items? Or, for more generalized item counting, where you will need to capture a lot of data at once? The effectiveness of RFID is influenced by the device’s beamwidth and gain. RFID antennas transmit radio waves outward and spread in a cone-like shape. Beamwidth refers to the widest spread of this cone. Simply put, the larger the beamwidth, the more coverage an RFID scanner will have. Gain refers to how effectively an antenna can receive or transmit a signal in a single direction. Generally speaking, the wider your signal spreads, the shorter the distance it can travel. So, the gain will increase with a smaller beamwidth, as a more focused beamwidth will increase the strength of the transfer in a given direction.

Since gain only measures the amount of existing power transferred, decreasing or increasing beamwidth will not affect the overall amount of power used.

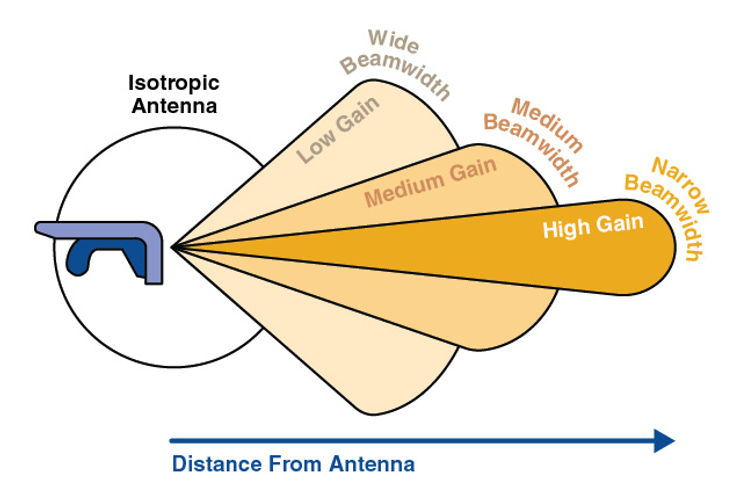

Signal Strength

Some RFID devices allow you to adjust the signal strength by modifying the amount of power used to achieve optimal gain. Power is measured in Decibels per Milliwatt (dBm). The higher the dBm, the stronger the signal. Because gain is the overall efficiency of an RFID device in a single direction, we need a standard unit to compare it to. This theoretical unit is called an isotropic antenna. This theoretical antenna radiates power equally (isotropically) in all directions, creating a sphere. When we compare directional gain to the isotropic antenna, the unit is measured in Decibel Relative to Isotropic Gain (dBi), also called Decibels Isotropic.

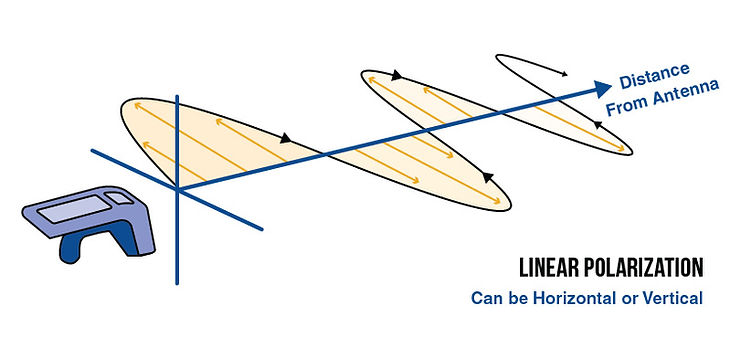

Polarization

Polarization also plays a major role in the success of an RFID system. Signal polarization refers to the orientation of the wave when it is being transmitted through an antenna. Polarized waves travel in a controlled pattern in a specific direction, while unpolarized waves move freely in multiple directions. When the electromagnetic waves oscillate along a single, consistent plane, it is called linear polarization. This plane could be horizontal or vertical, but the signal always travels in this fixed direction. Because of this, linear polarized antennas have a further read range but work best when the RFID inlay position is known and consistent. Antennas that are not aligned can result in read errors and poor performance.

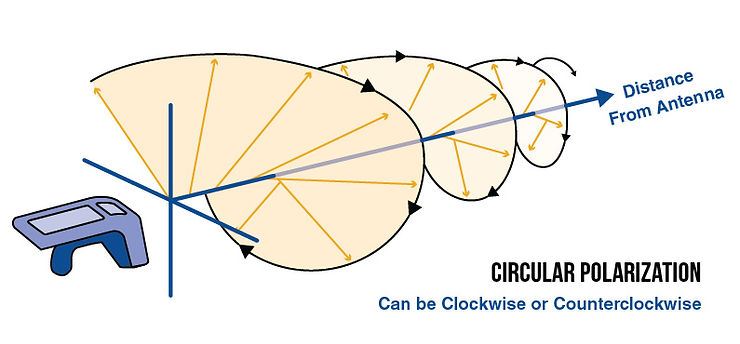

If you work in an uncontrolled environment where the inlay position may vary, circular polarized antennas will work the best! Circular polarization occurs when electromagnetic waves spin around an axis in a structured, corkscrew-like fashion. This circular motion provides a more consistent reading of RFID inlays, regardless of orientation or position. However, because the signal rotates, the energy will disperse faster, causing shorter read ranges.

Examples

Are you still confused about how all of these concepts work together? Here are some examples of RFID uses and the ideal RFID antenna for these settings.

Enhance security to control personal access and operations.

Instead of using passwords or key codes, RFID is commonly used to increase security by limiting access. For example, an RFID inlay in an employee badge can be read by the antenna connected to a secured door or equipment.

- Ideal Frequency: LF or HF

- Beamwidth and Gain: Low beamwidth with high gain

- Polarization: Linear

This antenna setup gives a focused, short, and accurate reading without using much energy.

Manage and monitor inventory in a warehouse or retail setting.

This is one of the most common uses for RFID. Inventory counts that used to take hours of labor can be done by a single person in minutes with RFID.

- Ideal Frequency: UHF

- Beamwidth and Gain: Medium beamwidth and gain

- Polarization: Circular

Consider the size of your space when determining the proper beamwidth for your RFID scanner. A smaller retail space would benefit from a higher beamwidth as the signal does not need to travel as far. While a large warehouse may need a scanner with a higher gain to read items further away. An RFID scanner that allows you to adjust power levels can help find the right balance between beamwidth and gain. If your warehouse stores a lot of metal or liquid items, where a UHF inlay may struggle, consider using a hang tag rather than a label for your inlays. The extra space between the tag and the item can greatly improve readability!

Track and locate assets as they move throughout a facility.

Does your workplace involve a lot of moving parts? Expensive equipment that moves between different departments? Units that, if you do not have on hand or cannot find, will shut operations down? RFID allows you to both track and locate items.

- Ideal Frequency: UHF

- Beamwidth and Gain: High beamwidth with low gain

- Polarization: Circular

Ultra High Frequency paired with a high beamwidth RFID scanner with wayfinding capabilities will give the longest read range with the most coverage. Scanners with wayfinding (also known as a Geiger search) can help pinpoint lost items and minimize losses. Passive scanners placed at entryways or elevators can automate tracking by letting you know an asset’s last known location. This method is commonly used by medical facilities to track expensive equipment that is frequently moved from room to room.

Manage loss prevention as items enter or leave a building.

Global retailers have perfected this method to not only manage inventory but also identify stolen goods. They aren’t the only ones! Manufacturing facilities use a similar setup at loading dock stations to instantly inventory items that enter the facility.

- Ideal Frequency: UHF

- Beamwidth and Gain: Low beamwidth with high gain

- Polarization: Circular

This setup uses three RFID scanners (one to the left and right of the door and one above) that all work together to scan all RFID inlays regardless of their position. Even if one scanner misses an inlay due to an obstacle, the other two will capture the data! As such, these scanners can get away with a lower beamwidth to get a more targeted scan of only the items that pass through the door, rather than any items that might be near the door.

Automate quality control with in-line production monitoring.

Traditional quality control methods rely on manual data collection and entry, leaving room for human error. RFID enables continuous line monitoring, allowing issues to be addressed in real time. RFID can also track performance metrics and maintenance schedules on machinery, keeping the line operating smoothly and minimizing costly downtime.

- Ideal Frequency: UHF

- Beamwidth and Gain: Low beamwidth with high gain

- Polarization: Linear or Circular

The polarization used will greatly depend on your production line. If the units are placed consistently, linear polarization would be ideal. If the units’ position on the line varies, circular polarization will work best.

The applications of RFID are limitless! These are just a few generalized examples to show how antenna configuration can help RFID perform best in those environments. What problem you intend to use RFID to solve may be different or could be a mix of these examples. For example, retailers that use RFID to manage inventory can encode product expiration dates on their inlays to help monitor quality. The same inlay and scanner used for inventory management also allows them to track and locate expired products, saving them labor costs by automating quality control procedures.