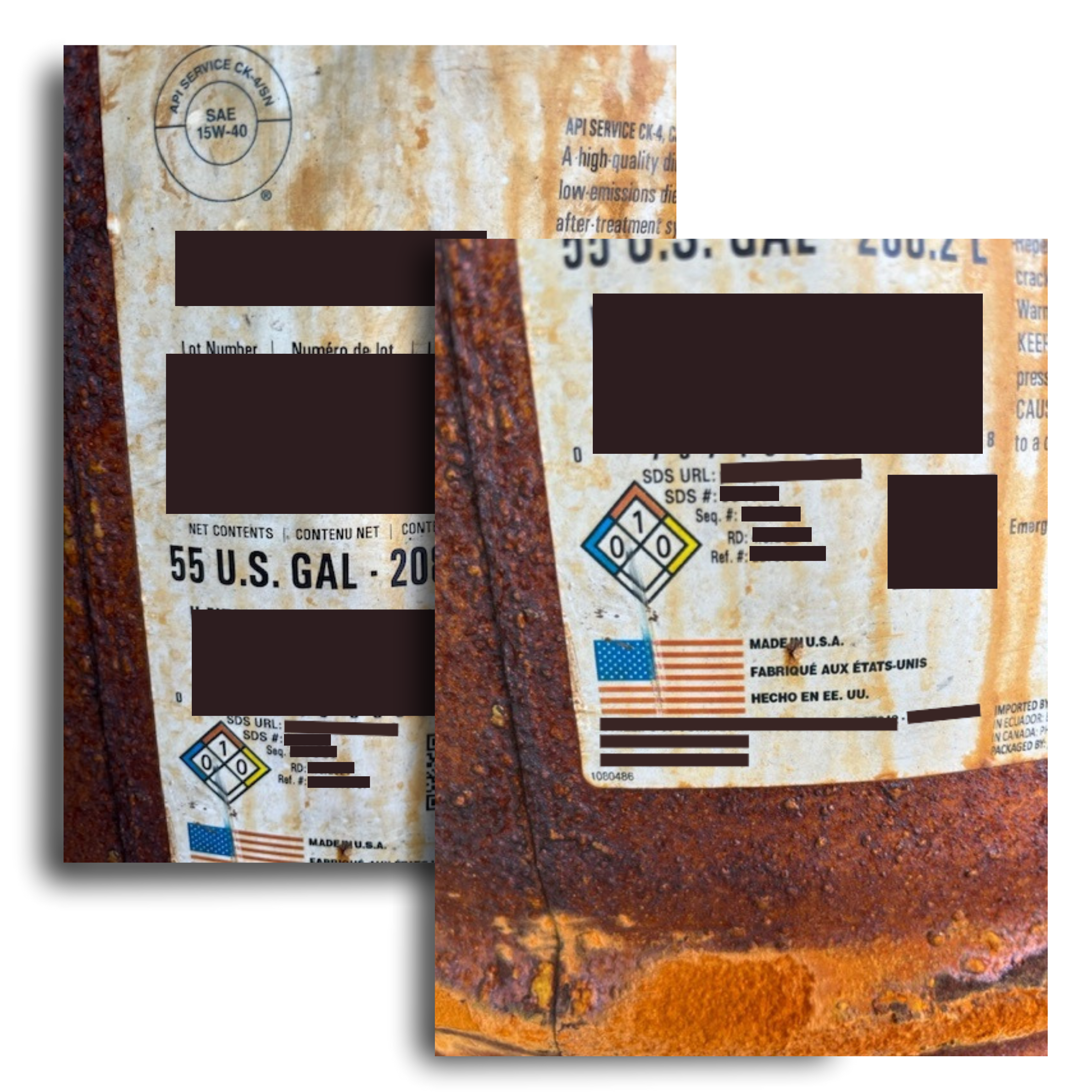

According to regulations, any hazardous material must have a safety communications label adhered to the outside of the container. The label itself is subject to many compliance rules, such as BS5609 Sections 2 & 3, governing the permanence and durability of the content imaged onto the label as well as the physical durability of the label. Reliance specializes in these types of products and the systems that create them.

The label on the floating drum detailed the materials within the container along with contact details for the producer. After tracing the label to a batch printed through Reliance’s Vision GHS Software, the team was able to identify the owner and origin of the container: a marketer of the larger material manufacturer.

Brent Spackman, creator of Vision stated, “This is the beauty of Vision. This is the essence of why it was created: visibility and tracking.” This case perfectly illustrates the importance and purpose of hazardous container labels as well. Had the label not been legible, the container may have remained unidentified, contaminated the environment, damaged boats, or injured someone.

Investing in quality, durable labels can make the difference when the containers are lost in the water. Safety communications are critical to protecting anyone who comes into contact with the material—from employees to pedestrians. There’s always risk when handling hazardous materials, but effective labels and hazard communications can greatly mitigate that risk.